Custom automated Inventory Management systems [IMS] may be the prerogative of the bigger enterprises due to the sizable upfront investment, but it has many advantages, including customizability, scalability, and business case fit.

With the hybrid nature of any retail tech stack, ERPs, CRMs, POSs are connected to dozens of third-party software solutions. In this setup, even an out-of-box automated inventory management system can be customized to fit the needs of the business.

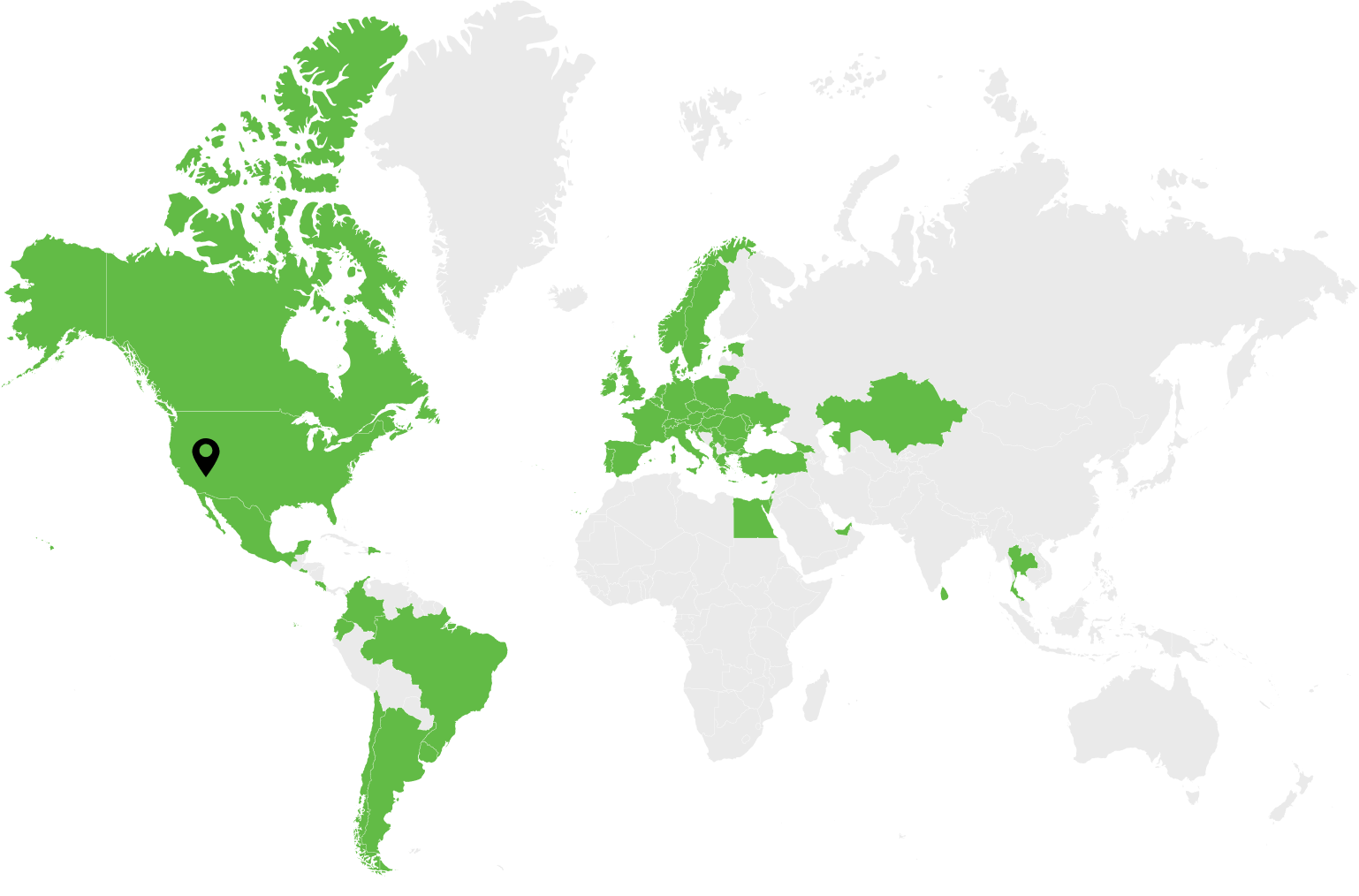

The Global Market Insights report illustrates the popularity of IM systems, which will see its market size grow at a CAGR of 5%, from $3 billion in 2019 to over $5 billion in 2026. Naturally, digital transformation in retail is a catalyst for such a robust surge, as the share of the ecommerce market grows in comparison to physical store retail.

An increased expectation of same-day delivery has pushed the industry to automate storage and delivery processes in order to remain competitive.

In this piece, we delve into all things retail inventory management, including trends, suppliers, importance, features, and custom development.

What Are Automated Inventory Management Systems?

Automated Inventory Management Software is a system that facilitates controlled storage and delivery of items, from the stage of raw materials to finished goods, by providing tools to track inventory, manage vendor relations, orders, and purchasing.

Automated versions of this software maximize the autonomous nature of the process, whereby materials and goods move along the supply chain with minimal intrusion of human operators. IoT, big data, ML, and IA technologies help expand the suite of automated services in the IMS.

Types of the IMS

The scope of the warehouse and inventory software is expansive. Almost every item you encounter on a daily basis was tracked by several of these solutions, from the manufacturing stage to the purchase of the finished product.

Deployment types include cloud, hybrid, and on-prem IMS systems. Based on the application of the software, there are solutions that specialize in order management, inventory optimization, asset tracking, and product differentiation.

Depending on the underlying technology, there are three main types of Inventory Management Solutions:

- Manually Managed Inventory Systems

- Advanced Radio Frequency Systems (RFID)

- Barcode Scanning Systems

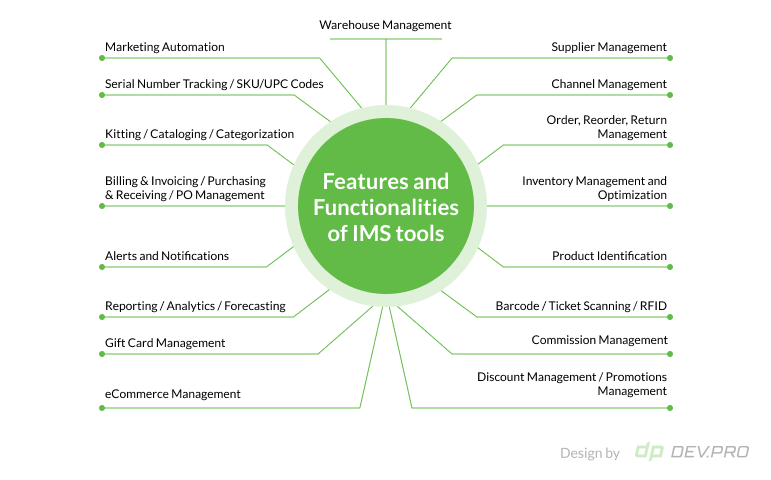

Features and Functionalities of IMS tools

In accordance with the size of the enterprise the software is designed for, industry, scope of applications, the range and selection of functions will differ. These are main features of such tools:

- Warehouse Management

- Supplier Management

- Channel Management

- Order, Reorder, Return Management

- Inventory Management and Optimization

- Product Identification

- Barcode / Ticket Scanning / RFID

- Commission Management

- Discount Management / Promotions Management

- eCommerce Management

- Gift Card Management

- Reporting / Analytics / Forecasting

- Alerts and Notifications

- Billing & Invoicing / Purchasing & Receiving / PO Management

- Kitting / Cataloging / Categorization

- Serial Number Tracking / SKU/UPC Codes

- Marketing Automation

Such tools may be designed for touchscreen operation, multi-location units, cloud, hybrid or on-prem deployment, mobile or desktop, and can include layered access levels.

Globally, inventory management systems are used in healthcare, oil & gas, manufacturing, automotive, as well as a host of other industries. Each of these industries will demand different adjustments and customization to fit the needs of their particular operations.

This article focuses on the trends and benefits of IMS in retail and ecommerce.

Retail Trends that Define the Future of the Inventory Management Industry

The fast moving retail industry requires tools that serve its ever-changing needs. These trends define what is expected from the retail software in 2022:

- Last-minute or Same-day Delivery

Grocery delivery of highly perishable merchandise has attracted billions of dollars in investment, with a particular focus on last-mile delivery startups.

According to a PWC survey, 41% of consumers are willing to pay extra for same-day delivery and 24% are fine with paying even more to get their purchases in 1-2 hours.

In fact, a fulfillment service survey reveals that, despite 75% of customers wanting same-day delivery, only 50% of retailers actually offer it.

The use of cloud technology, microservices architecture, ML, and real-time reporting are all must-have requirements for a modern IMS to comply with these time-critical technical tasks.

- Curbside Pickup

Click-and-collect purchases doubled in the U.S. between 2019 to 2020, reaching $72 billion in annual sales. Driven by retail behemoths like Walmart, Home Depot, Best Buy, and Target, the trend is likely to continue with double-digit growth forecasted over the next 4 years.

This retail trend is also supported by IMS vendors as well as kept on the radar of the software development companies that offer custom-made IMS solutions. In order to enable the smooth service, you need to organize your in-store and curbside logistics and ensure seamless integration of the POS, ecommerce platform, payment solution, and the inventory management app.

- Contactless

Contactless is the new norm for vendors, warehouse employees, and customers. This has led to an exponential increase in RFID technology and barcode scanners.

IoT integration is vital for businesses developing custom retail management software and requires significant functional and non-functional testing.

- Social Distancing Requirements

Social distancing, lockdowns brought a whole new focus on the automation of warehouse, storage, and logistics processes.

Drone technology, computer vision, smart shelves, and other tech solutions can be used to reduce the reliance on human staff in warehouses, delivery, and in-stores.

Importance of Inventory Management: Real-World Examples

The importance of inventory management is no longer focused on saving lives (as was the case when products had to be preserved to prevent starvation or in case of medical issues). However, inventory management is still a major factor when it comes to global issues like reducing a company’s environmental footprint, fighting poverty, and managing pandemics.

Above all, the difference between a well-designed inventory management chain and poorly operating one is the difference between the market leader and the outcast.

The line between disorder and order lies in logistics…

Sun TzuThese aspects are fundamental to the weight of automated IMS in today’s global economy, and is particularly important in retail:

Speed of Product Movement Along the Supply Chain

Speed is one of the competitive advantages for all parts of the supply chain. In fact, in some cases it rivals the significance of fundamental customer satisfaction elements like price and quality.

Automation makes order processing quicker, more controlled, and less dependent on human factors.

Sharjah Cooperative Society (SCS)

A cooperative founded in 1977 in the UAE, which employs over 2,400 professionals, started a partnership with SAP as one of the prominent digital transformation partners in retail.

The company automated its inventory management process, which reduced its annual stocktaking procedure from three weeks to five days. Inventory replenishment process automation was also successfully implemented as part of this cooperation.

Reduced Labor Costs Feature in Automated Inventory Management Systems

In some European countries, the cost to hire local workers is prohibitive, leading some companies to hire recent immigrants and visa workers for warehouse and supermarket jobs.

With automated inventory management, labor costs can be reduced as man-made functions are replaced by drones, RFID and other IoT devices.

Omni-Channel Reach to Customers

Omni-channel practices in retail are on the rise, a trend that has been accelerated by the growth of social distancing. Contactless forms of delivery, like click-and-collect and curbside pick up are on the rise.

The Manufactum Group

The Manufactum Group wanted to have better visibility of its inventory as one of its approaches to digital transformation. The SAP CAR [Customer Activity Repository] tool provides this feature.

The rollout of three retail management software solutions — OmniPOS by GK, SAP CAR, SAP HANA — supports the brand’s much-awaited omni-channel features: Click & Collect, Click & Reserve or WebOrder and StoreReturn.

Digital Transformation Roadmap In RetailBalance Between Overstocking and Understocking

eCommerce is growing its share [18% in 2020], pushing into the retail store market. This is where both overstocking and understocking have dire consequences.

Businesses need to determine the balance between marketing efforts, purchasing capacity, storage and warehouse turnover allowance, and shipping capabilities to minimize long-term damage. This is where inventory management systems can help.

Competitive Advantage for Perishable Goods and Groceries

Perishable goods are a high-risk business where storing conditions and speed of delivery are crucial to getting to the break even point. On the other hand, it’s a high margin business due to higher risks and lower competition and is particularly lucrative for those that can manage their supply chain.

- FIFO [first in first out], the principle that produce purchased earlier should be sold first, is fundamental in the perishable goods business.

- Inventory tracking needs to be organized so that warehouse managers have full control of incoming and outgoing cases and can make decisions on the fly, adjusting or canceling future orders based on demand.

- Single period stocking rules should be used to avoid overstocking. In the best case scenario, MOQ is purchased initially to test demand and further purchasing follows the single period stocking principle.

Better Planning, Forecasts, Predictability of Business Processes Based on Data

In the world of retail and ecommerce, even little things can have a big impact due to the scale of the business, where margins are rather low.

This is why the role of data and analytics gets even more weight in this domain.

Without data, you’re just another person with an opinion.

W. Edwards DemingWalMart

WalMart Stores Inc., the indisputable leader in retail, made the switch to SAP S/4 Hana in 2015 in order to use its data more efficiently in the decision making process.

Not only does the ERP have a number of modules that fulfill inventory management functions [asset management, supply chain, sourcing], but it enabled the company’s 2.2 million employees to get a tight grasp of terabytes of data, completing 94% of queries within 2 seconds.

Retail Inventory Management Trends

Current industry trends define the goals of inventory management and its future. These are just some of the up-to-the-minute tendencies.

3PL

Infrastructure is an asset, but it comes with a price. Third-party logistics are often the chosen approach for smaller and mid-sized retailers, which take advantage of the warehouses and logistics supplied by these providers instead of building their own infrastructure.

This trend in the retail business supply chain dictates that most of the software solutions need to be easily integratable with each other for two-way instantaneous data flow.

Cloud deployment

In industries like retail, near real-time updates of the stock can mean more sales and better marketplace rankings.

Cloud technology offers access to data from anywhere while ensuring high levels of security and fast computing capacity.

Retailers with multiple outlets can get real time access to inventory management requirements and fluctuations for birds-eye view decision-making.

Reporting and analytics

Just-in-time inventory is the optimal stocking method for many retail businesses, but it needs a lot of historical and seasonal data to implement.

Data visualization makes forecasting and managing demand, expiring products, shipments, delays, overstocking, and manning much easier. When data is translated into graphs and charts, it becomes easier to spot peaks, anomalies, and trends. The industry consensus is: start collecting data, even if you don’t know how it can help you make your business better now. It will come handy in the future.

How to Improve Retail Inventory Management

There are dozens of ways how to improve inventory management. The biggest question to ask yourself is if you want a custom automated inventory management tool or a ready-made system.

If your choice is an out-of-the-box solution, there are a few things you can do:

- Review all major global and local vendors with similar products

- Review your subscriptions plan and pricing rates in the contract for any right-costing opportunities

- Review your cloud vendor packages and services and conduct full audit in terms of both: right-sizing and right-costing.

- Conduct an audit and implement API connectivity enhancements between major tech stack units, like ERP, CRM, POS etc.

- Get structured feedback from team, partners, and vendors in terms of features that need improvement or take up space and go unused.

These initial steps will be a good starting point to take your system to new levels, aligning it with the most recent business requirements.

If you prefer to develop a custom inventory management system, the first step is a full audit of your tech stack, as the IM tool needs to be connected to a financial system, purchasing, CRM, ERP, and POS at minimum.

The next step is to define your prime features, which involves deciding on the modules you need most and the ones you can roll out later. Then it’s time to estimate your budget, timeline, and start looking for an outsourcing vendor.

If you are new to the topic, consider a quick, free discussion with our sales team. Fill out this form with as much detail as you have at hand and our experts will work with you to ascertain your needs.