Learning from the best is a proven tactic to gain muscle memory quickly in any field, particularly in matters as multi-layered as supply chain digital transformation [DT].

In order to understand the topic, let’s start by reverse-engineering the success of Cisco, the global leader in SCM [Supply Chain Management].

John Kern, Cisco’s senior VP for supply chain operations mentioned some of the company’s success factors for its digital transformation strategy. Here’s a summary:

- Agility and resilience are not cheap and worth investing in.

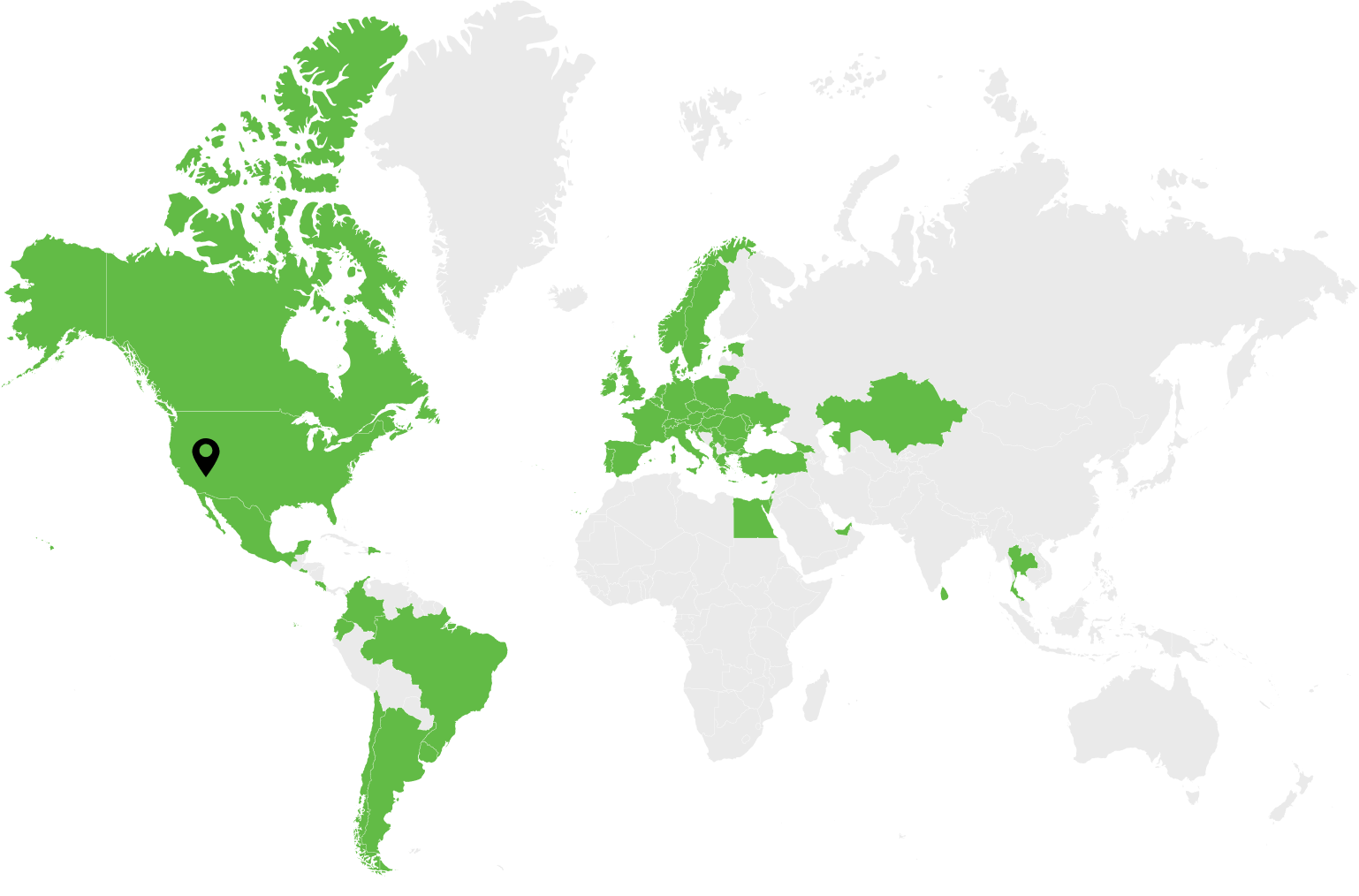

- Focus on creating a dynamic distributed supply chain: consider dual sourcing, minimize risks by investing in diverse geographic regions, and create strategic partnerships with suppliers.

- Strive for a greener supply chain always: cut company-generated greenhouse emissions, reduce foam in packaging, and implement circular design principles.

- SCM starts at the planning stage and belongs there — it precedes R&D, it doesn’t come afterward.

“We’re very aggressive in shifting to a more digital supply chain, leveraging cloud technology, artificial intelligence, machine learning and IoT. And harnessing the value and embedding those technologies into many, many practices.

John Kern, Cisco senior VP supply chain

Inspired yet? Let’s delve into the key questions related to digital transformation in the supply chain.

What is Digital Transformation in Supply Chain Management?

Before diving into the definition of supply chain management digital transformation, let’s first define what SCM is about.

What is Supply Chain Management?

Supply Chain Management is a multi-faceted system of centralized activities, methods, and tools that enable the flow of the goods from raw materials to fulfillment of finished products to the end consumer’s door. This ecosystem includes planning, sourcing, manufacturing, delivery, and return handling.

Defining Digital Transformation in Supply Chain Management

Digital Transformation of the SCM is a complex set of activities that help simplify, automate, and systemize all functions of the supply chain with the aid of technology. It involves website and application development, social media, telephony, chat, SMS, email marketing, and IVR [Interactive Voice Response] technology. System integration is vital for successful DT, — it interconnects business processes and helps integrate a company’s website, ERP, CRM, WMS, IMS, sales, and logistics software into one system for better visibility, control, and decision making.

As we approach a blueprint for how to start Digital Transformation in Supply Chain Management, this final diagnostic chapter reveals the pains and restrictions the industry faces post-pandemic, which DT can help alleviate.

Why are Changes Needed in the Supply Chain Sector?

The pandemic precipitated digital transformations for dozens of industries. Logistics and supply chains are undergoing a major evolution too.

Resilience and Business Continuity over Price Efficiency

The pandemic’s onset highlighted one major weakness in the supply chain: cost efficiency comes at a price. Before the pandemic, all links in the supply chain had targeted a reduction in price, often at the expense of a loss of resiliency and business continuity.

But nearly overnight, price was no longer an issue. The price of a 40-foot container went from $2,000 to $25,000 in two years of pandemic.

Such a shift in the supply-demand paradigm made companies rethink their approach to competition. They needed to regroup and find the balance between cost, speed of delivery and guarantees.

Consumer Expectations of One-Day or Same-Day Delivery

Consumers expect things to be available with a click. Amazon invested $800 million in just one quarter of 2019 to shorten the default Prime delivery term from 2 days to 1 day.

Spencer Fung, CEO of supply chain manager Li & Fung, echoed the significance of speed at a National Retail Federation conference. This is how he replied to high-end brands facing the same pressure to speed up and digitize as a mass merchants:

“We see a world where everything eventually will be digitized and when you digitize processes and businesses, velocity actually increases. So if you don’t digitize parts of your business, you will forever be in the low velocity world. And in a world where consumers are speeding up and they are changing preferences on a minute-by-minute basis, even the luxury brands will have to invest.

Spencer Fung, CEO of Li & Fung

Risk Management and Tier 2 and 3 Visibility

According to a Vuealta study, 30% of companies were subject to disruptions due to the failure of a single supplier. Geopolitical issues, natural disasters, reputation management, and visibility of tier 2 suppliers are all subject to risk management activities in the supply industry.

With the proliferation of blockchain technology, IoT, AI, computer vision, and big data, the industry gets more and more tools to proactively address these challenges.

Labor and Safety Issues: Continuous Public Focus

As smartphones become omnipresent, labor and safety concerns rapidly decrease and manufacturing and logistic companies are spurred into action by fear of public disclosure by whistleblowers. For example, companies invest into creating proper working conditions and stop hiring underaged workers in Asia, because of fear of video evidence of unethical conduct in the Western media.

Corporate Social Responsibility has evolved to better control the working conditions of employees. Yet further digital transformation activities and tools are needed to fully eradicate similar labor and safety issues.

Unethical sourcing is another issue of concern in this domain. Top Glove Corp, a rubber glove manufacturer, picked up a hefty bill for using forced labor when its IPO got delayed over a ban issued by the U.S.’s Customs and Border Protection.

There is a huge disconnect between the priorities of the labor and safety of the developing world and developed countries. Safety Management Software and EHS solutions help address these concerns.

Environmental and Social Governance [ESG]

ESG practices are relatively new but they demand a lot of focus from the industry leaders to comply and even mold this new corporate framework and philosophy.

Sustainability, human rights, an environmentally conscious mindset, consumer protection, and employee rights all make use of technology to move forward.

Best Practices for Rolling out Digital Transformation in Supply Chain

These empirical best practices will help implement digital transformation initiatives throughout the organization if you are looking to integrate vendor-made solutions or opt to develop a custom SCM system.

Consult Several Digital Transformation Experts

Before starting to choose a tech partner, reach out to a few software development companies for a consultation.

Even if you have to pay for an audit, review of your status quo and a digital transformation roadmap, you will have ended up with an invaluable set of expert opinions that will save you loads of resources down the road.

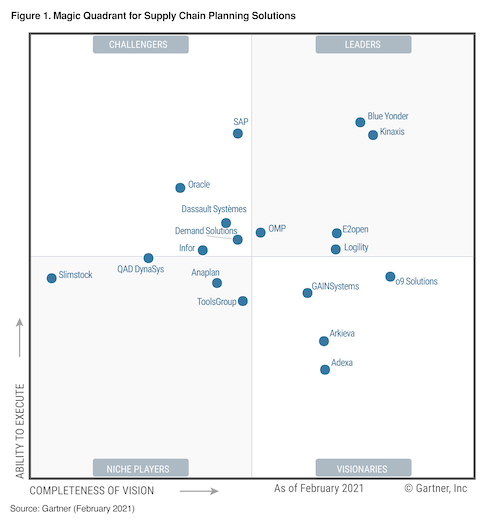

Consider Multiple Vendors for Each Service, Look for Visionaries

When choosing a SCM software vendor, make sure to consider at least 3-5 companies and include younger tech solutions, like those who place into Gartner’s Visionary quadrant. They often turn out amazing value-for-money with cutting edge features.

Align Digital Transformation Goals with Business Priorities

Choosing your priorities is vital, as is aligning your technical arsenal to your company-wide goals.

If you are an international logistics company, translating your SaaS solution into major languages is a top priority, as well as ensuring compliance across borders and currencies.

Optimize Cloud Cost in Line with Best FinOps Practices

When developing your supply chain digital transformation strategy, ensure you integrate the cloud cost optimization best practices into the architecture of your systems. With multiple cloud services and subscriptions used for a diverse range of tools within the company, some regular rightsizing and right costing measures can lead to five or six figure savings.

Follow the Demand and Make Data-Driven Decisions

Demand-driven supply chain management is now a reality with predictive analytics, AI, ML, drone inventory-taking, and barcoding tech. Data is capable of providing more answers to optimize the business processes across all stages of the material sourcing, manufacturing, and delivery. Ongoing business process optimization is best incorporated into the monthly meeting schedule.

The below overview of the top SCM suppliers will help you understand the fundamental features and functions of the future ecosystem. For an even deeper understanding of the subject, you may also want to check out our piece on an industry tightly connected with SC: Digital Transformation in Retail: Trends That Can Drive Your Growth

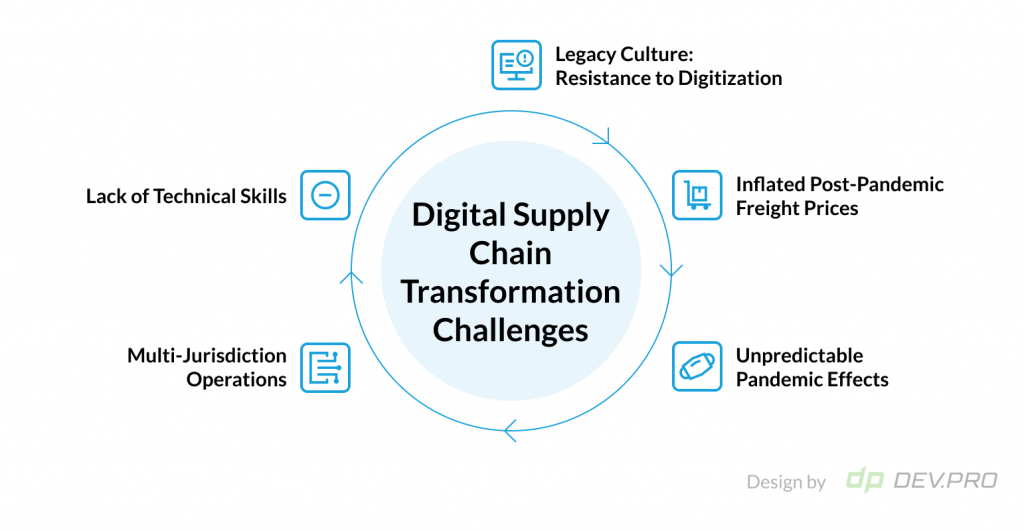

Key Digital Supply Chain Transformation Challenges

The challenges of the industry are legacy-derived as well as post-covid-related.

Legacy and Corporate Culture Resistance to Digitization

There is a lot of on-prem software still in the industry, but cloud technology offers so much agility and ensures minimal downtime and disruptions. Creating a corporate culture that welcomes and embraces technical change is vital.

Inflated Freight Prices: Temporary or the New Norm?

It is not yet clear if the prices will even out as business returns to normal.

Unpredictable Pandemic Effects

It’s unknown how long and severe the next stages of pandemic may be, which incapacitates forecast or ordergoods and services. This particularly affects those with long production cycles.

Multi-Jurisdiction Operations

Many logistics and delivery companies operate across borders. Complying with ever-changing regulations across different jurisdictions is a resource-draining mission.

Lack of Skills: Path to Team Extension or Managed IT Services?

Servicing digital chain supply logistics transformation requires a lot of technical talent and know-how. Software developers, cloud specialists, blockchain engineers, and DevOps experts are just a few of the tech talent pool needed to customize and integrate multiple software solutions for warehouse, logistics, and order management.

Hiring an outsourced team of software engineers or signing up for managed IT services or getting a team extension for your internal IT department is often a sensible way forward.

Supply Chain Management Software: Status Quo, Leaders, and Features

Custom-made Supply Chain Management Software is currently rare due to the proliferation of cloud technology and affordable SCM SaaS solutions. These are usually integrated with ERP, CRM, S&OP, financial, inventory management software, and other company-adopted SaaS systems.

Supply Chain Management Software Market Stats

According to a Research and Markets report, the Supply Chain Management software market was worth $14.6 billion in 2019, and is predicted to grow to $19 billion at a five-year CAGR of 6.7%.

Out of the $17.3 billion in revenue forecasted for the market in 2021, $8.7 billion was generated in the U.S.

The market is usually subdivided into the following segments:

- Supply Chain Planning Solutions

- Procurement Software

- Transportation Management System

- Warehouse Management System

Supply Chain Planning Software Features

Many of the SCM solution types have transient features, so let’s list those for Supply Chain Planning, as they are likely to be present in other types:

- Supplier management

- Warehouse management

- Transportation management

- Inventory management

- Order fulfillment

- Electronic Data Interchange [EDI]

- Sale & Operations Planning

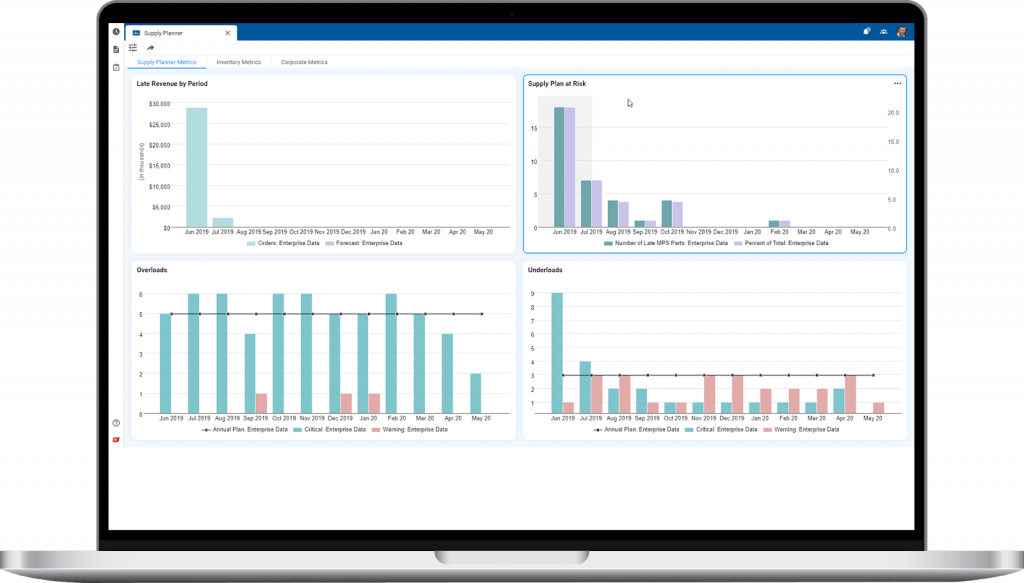

- Demand Forecasting with Predictive AI Features

Supply Chain Planning Software Major Vendors

Gartner’s Magic Quadrant for Supply Chain Planning Solutions places Blue Yonder, Kinaxis, E2open, Logility, and OMP in leadership roles and positions SAP, Oracle, Dassault Systems, Demand Solutions, and Infor as challengers.

Blue Yonder recently announced the acquisition of Panasonic, which lays the path to a yet another revolutionary spin of this leading technology.

In a speech , the CEO of Blue Yonder, Prakash Seshadri, emphasized four areas of focus for a Panasonic-enabled company:

- Industrialization of the supply chain;

- New opportunities to realize the “Power of three” combining Panasonic’s Edge with Cloud technology and AI/ML;

- Transition of the center of gravity and responsiveness of supply chain from the C-suite to frontlines;

- Real-time visibility and control as the default setting in the post-pandemic reality.

Source: Twitter

Benefits of Digital Transformation in Supply Chain Management

Digitizing your SCM may seem overwhelming, but there are rewards to look forward to:

Velocity

Pandemic revealed a major fault of the system focused on the cost effectiveness above all. But velocity proved more valuable in the end. Continuity of business and velocity in crises are also facilitated by new technology that’s embedded into various SCM software systems.

Speed

One of the most obvious advantages of automation is speed of processing. It takes drones about ten times as little time to do stock inventory than it takes humans, for example.

Transparency

From ethical sourcing and transparent pricing to executive bonuses and environmental impacts, supply chains would benefit from more transparent methods, tools and outputs. Digital supply chain transformation offers transparency as it’s core pillar where big data, blockchain, AI, ML serve to make data accessible for all stakeholders. This includes the manufacturers, logistics companies, warehouses, governmental institutions, and the end user.

Accuracy

Human work is prone to errors, so with the rise of IoT, computer vision and barcode scanning technology, warehouse inventory management is getting more precise and accurate.

Cost efficiency

While there are multiple use cases about supply chain digital transformation benefits, one example, given by Jon Chambers at P&G, showed how he helped one of the Lenor-producing plants save six figure amounts in warehouse rental. A simple data visualization with average daily shipment along the horizontal axis and coefficient variation of shipments along the vertical axis helped change the company’s production schedule, significantly reducing costs.

For the sake of the balanced view, let’s also consider key issues on the way to a fully digitized company in the supply chain industry.

How to Prepare Your Supply Chain Digital Transformation Strategy

The depth and breadth of the digital transformation strategy for your organization’s supply chain depends on a myriad of factors. They all include these stages:

- Full audit of the existing tech stack and online presence [from ERP, CRM, SCM, Cloud Services, to social network presence and digital media review].

- Understanding business goals in the short term and long term, and defining resources available [financial min-max amounts, talent pool, and deadlines].

- Finding how digital transformation can help bridge the gap between status quo and the goals while prioritizing the methods with quickest ROI.

- Elaborating a step-by-step roadmap with people responsible, deadlines and resources allocated to each activity.

- Implementing the roadmap internally or by hiring an outsourced digital transformation company.

DevPro’s team offers hands-on expertise in building digitally-savvy software products from scratch as well as helping drive digital transformation for forward-looking companies across FinTech, eCommerce, InsureTech, as well as supply chain industries. Fill out this form to schedule a consultation on your next step toward a fully digitized enterprise.