Even though it’s in the early stages, fast food automation has arrived. Big QSR operators routinely use robots to flip burgers, take orders, clean dishes, make french fries, and chop salads.

Staff shortages, food hygiene concerns, peak hour service bottlenecks, and inflated rental fees have made F&B players consider restaurant automation as a solution.

“In this market, employees will leave if they have one bad day,” –

Chief executive of Saladworks, Patrick Sugrue.

According to Square Future’s 2022 restaurant survey, “90% of restaurants agree that increased automation for back-of house operations would allow staff to focus on more important tasks.”

But it’s not only the feeble labor market that makes food operators turn to robotics — third-party delivery commissions can be as high as 30% of an order. Chick-Fil-A partnered with delivery robot KiwiBot in an attempt to lower delivery costs for the company and its customers. The bots can deliver food for $1.99 in under 30 minutes within a radius of one mile.

Let’s review the major benefits of food industry automation in detail.

Key Fast Food Automation Benefits

Better Food Safety

Many fast food chains will have a manual burger assembly system, which suggests some human contact. In the wake of the pandemic, food hygiene standards are a major area of concern for clients.

In a survey of over two thousand restaurant customers, 65% of respondents said they “would avoid eating at a place if they were not confident in food safety standards of the premises.”

A Creator burger assembly robot has fully automated processes from bun-cutting to plating, minimizing human contact and prioritizing food hygiene.

Rental Savings

The Creator Burger bot case reveals another advantage of automation: its compact nature. In cities with high rental fees like San Francisco, a compact island for robots is significantly smaller than the amount of space needed by human chefs.

In an industry with razor-thin margins, every cost saving measure goes toward increasing the feeble bottom line.

Waste Reduction

IoT devices with camera sensors are used to move bananas on the supermarket shelves according to FIFO principle — First In First Out. Similarly, IoT in kitchens and warehouses can help reduce the waste in a number of ways, from recipe weighting and purchase planning to produce movements on the shelves of storage rooms.

Lower Labor Costs

According to a McKinsey report, a record 73% of activities in the accommodation and food service industry can be automated technically.

The sheer number of mundane tasks in the FSR segment is leading the way, specifically as it relies on low-qualified personnel with weaker motivation levels and respectively high turnover rates.

Arby’s uses automation to reduce its working shifts. Their morning shift chefs don’t have to show up at 7 am anymore to start cooking beef for lunch. The cooking process is overtaken by a night shift, which uses automated settings to program the roasting timing.

Food Consistency

IoT sensors are frequently used by kitchen robotics. These devices can be used to monitor temperature, use cameras for precise ingredient placing, and measure weight.

A burger assembly on its own is a craft, whereby a burger needs to be flipped at a specific time for it to be cooked through, yet juicy enough, salt and pepper must be measured, pickles thinly cut, etc. Fast food chains and franchises pay attention to recipe consistency. Needless to say, robots are best at achieving this goal.

Increased Efficiency

There’s no such a thing as a resigning robot, that you need to rehire. There’s no such thing as a tired robot that needs a break in the heat of the lunch rush. There’s no such a thing as an absent-minded robot, who forgets something and creates a bottleneck in your peak service hours. You don’t need to spend resources hiring, training, or firing robots.

While they come with a substantial upfront investment, their further maintenance and performance turn into a positive ROI sooner rather than later.

Better Employee Safety

Not only can the robots do mundane repetitive tasks, but they can also do tasks with higher risk factors, reducing the probability of human injuries.

Types of Automation in Fast Food Industry

With all the benefits of automation in fast food, it’s safe to assume that the process is unstoppable and will be getting more diverse and imminent with time.

Front-of-House Automation

Self-Service Kiosks

Peak hours are bottlenecks for every food outlet out there for three reasons: breakfast, lunch, dinner. Your team is the most stressed at these moments, leading to mistakes and slowing down the congested service.

Self-service kiosks help address this issue, reducing long lunch lines in QSR. A survey revealed that 65% would be more willing to visit a place with a self-service kiosk. Once cashier lines exceed four people, customers prefer to order from the kiosk instead.

Robot Waiters

Automated robot delivery is already used in restaurants, though it’s still primarily a marketing gimmick. As the technology becomes more mature and RaaS options develop, businesses can experiment with small monthly subscriptions.

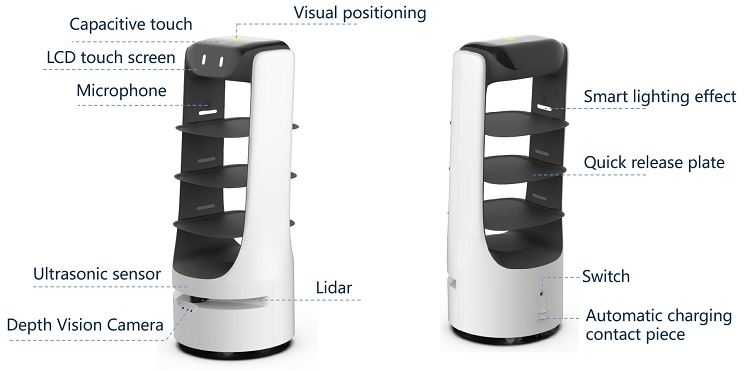

Robot waiters will usually have touch sensors, smart voice recognition, depth sensor, machine vision technology, and sophisticated navigation capabilities.

Voice Recognition at Drive-thru

Wendy’s is using voice recognition software to automate the order-taking and kitchen communication processes. There’s no more space for human errors or double-checking with the client.

Drive-thru ordering can be further enhanced by AI and big data. This is how: you know as you walk into your corner coffee shop every day, the barista asks you: You extra large almond latte with caramel? Just like that, armed with your license plates and face recognition technology, the next thing we know we may be offered our favorites by machines too.

Back-of-House Automation

The kitchen and warehouse parts of the restaurant business are highly dangerous environments with sharp objects, extreme high and low temperatures, and plenty of repetitive tasks — a perfect medium for bots.

Kitchen Robots: From Spreading Sauce on Pizza to Flipping Burgers

Miso Robotics announced the launch of its second generation burger flipping robot called Flippy 2 at the end of 2021. It’s now capable of doing twice as many food prep tasks, including basket filling and returning.

The company offers a novel model cooperation: RAAS: Robot as a Service. Flippy 2 is available starting at just $3,000 per month offering in return 2X faster food prep tasks and 30% more fried food throughout.

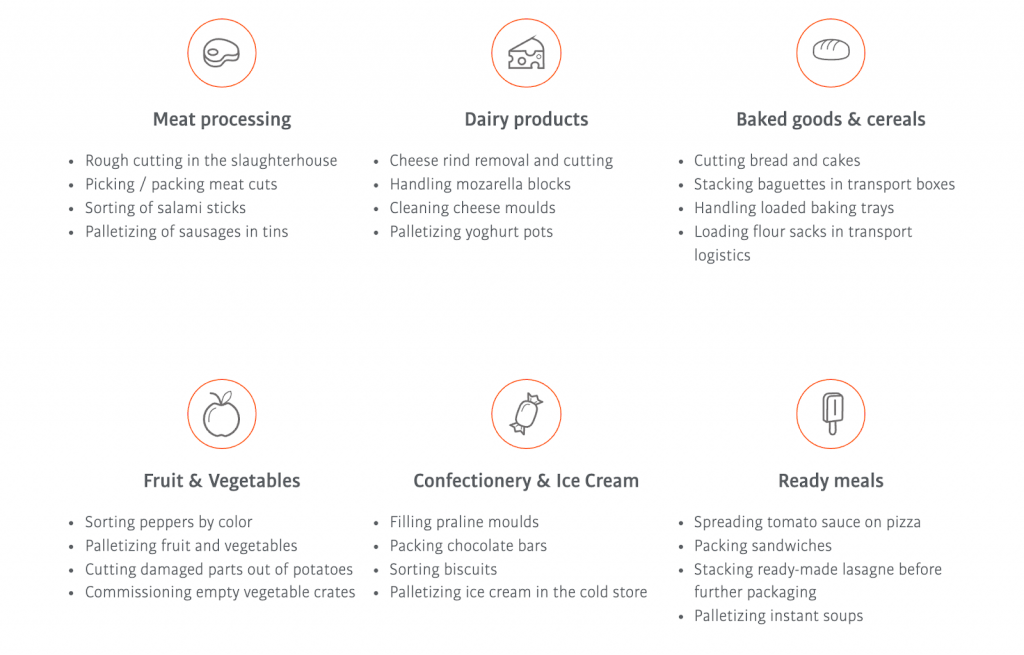

Kucka produces a number of products that help automate warehouse work and some processes in kitchens. Its solutions include robots that can operate under extreme temperatures like deep freezers or bakeries. The functions carried out by these robots include: palletizing ice creams in cold stores, cutting damaged parts out of potatoes, packing sandwiches, cutting bread and cakes and so on.

Dish Washing & Cleaning Robots: The Norm of Fast Food Automation

While washing machines have been used in professional kitchens for decades, they are also part of the bot army. They require humans to operate, load and unload, but the washing itself is done automatically under correct germ-killing temperatures and with respective detergents.

Even more automated solutions are in the pipeline. Moly is a kitchen robot for individual use, which is capable of cooking some dishes and washing up.

Dishcraft’s washing robots are a blessing for catering companies and corporate cafeterias, which need to go through thousands of plates for events.

Security and Disinfection Robots for Restaurants

Hygiene is a critical factor because customers want to know their food has been prepared in pristine conditions. Ava Robotics manufactures disinfection robots that are capable of cleaning the air and surfaces.

The same company offers security bots that can travel along the guarded parameters, capturing footage of everything they see, analyzing it for movements, and sending alerts. Patrolling, observing, and reporting are mundane security tasks that can now be automated.

Automated Delivery

Drone Delivery

Domino’s tried out drone pizza delivery to increase the speed of delivery, which is critical when it comes to fast food. While it has yet to be adopted on a broader scale, many companies in a variety of economic segments are considering this technology.

Delivery robots

Just like waiter robots, delivery robots are available as a RaaS solution. For example, Service Robots company rental rates start as low as $599 per month.

Due to the battery life and strength of the signal, the radius of their service as couriers is usually limited to just 1 mile. Still, given the demand for a steaming cup of coffee, the future is bright for the technology, especially in locations like student dorms and business hubs.

Hotter climates, like those in California, are more likely to be the home to this technology in the long run.

LCD touch screen, microphone, ultrasonic sensor, depth vision camera and automatic charging contact.

Fast Food Automation: Integrating All Systems For 360° Overview

Any piece of robotics in the fast food industry will use a set of technologies that make a robot see, feel, move, and hear — and they all need to be interconnected with software. IoT devices with temperature sensors, microphones and cameras are routinely used in robot development and need to be integrated with other hardware and software components.

As fast food restaurant automation attracts investments, the RaaS distribution model is seen as one of the major business development possibilities to move this industry forward. This is why almost any piece of automation in the fast food industry will have a software application with a reporting module, as well as a setting-type mission control for managing and programming the bot.

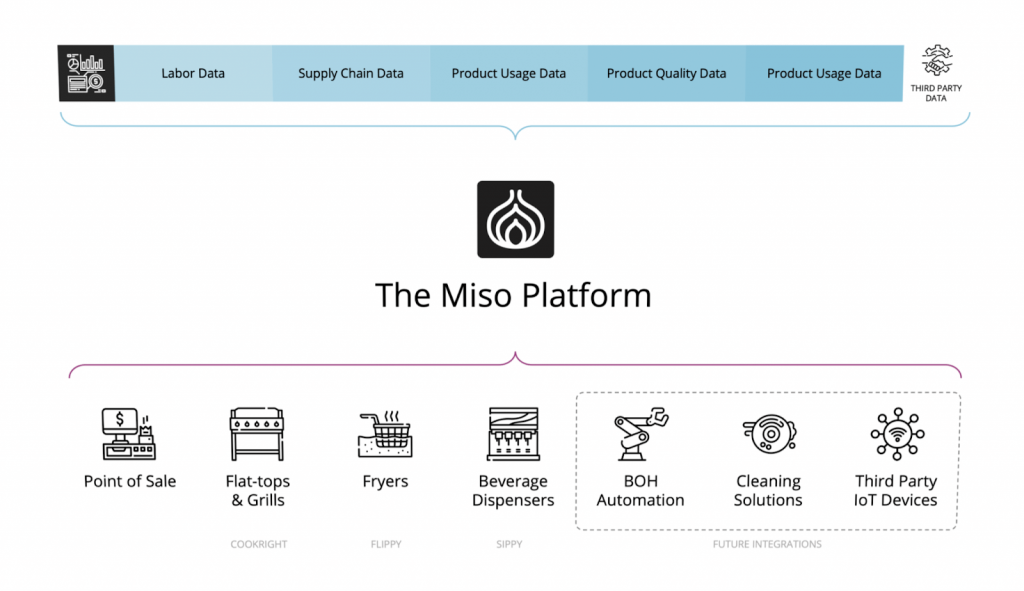

The multi-component nature of this technology demands for all systems — proprietary and third-party ones — to be integrated with each other. The Miso Platform combines a few sources in order to function, as is seen in the diagram below.

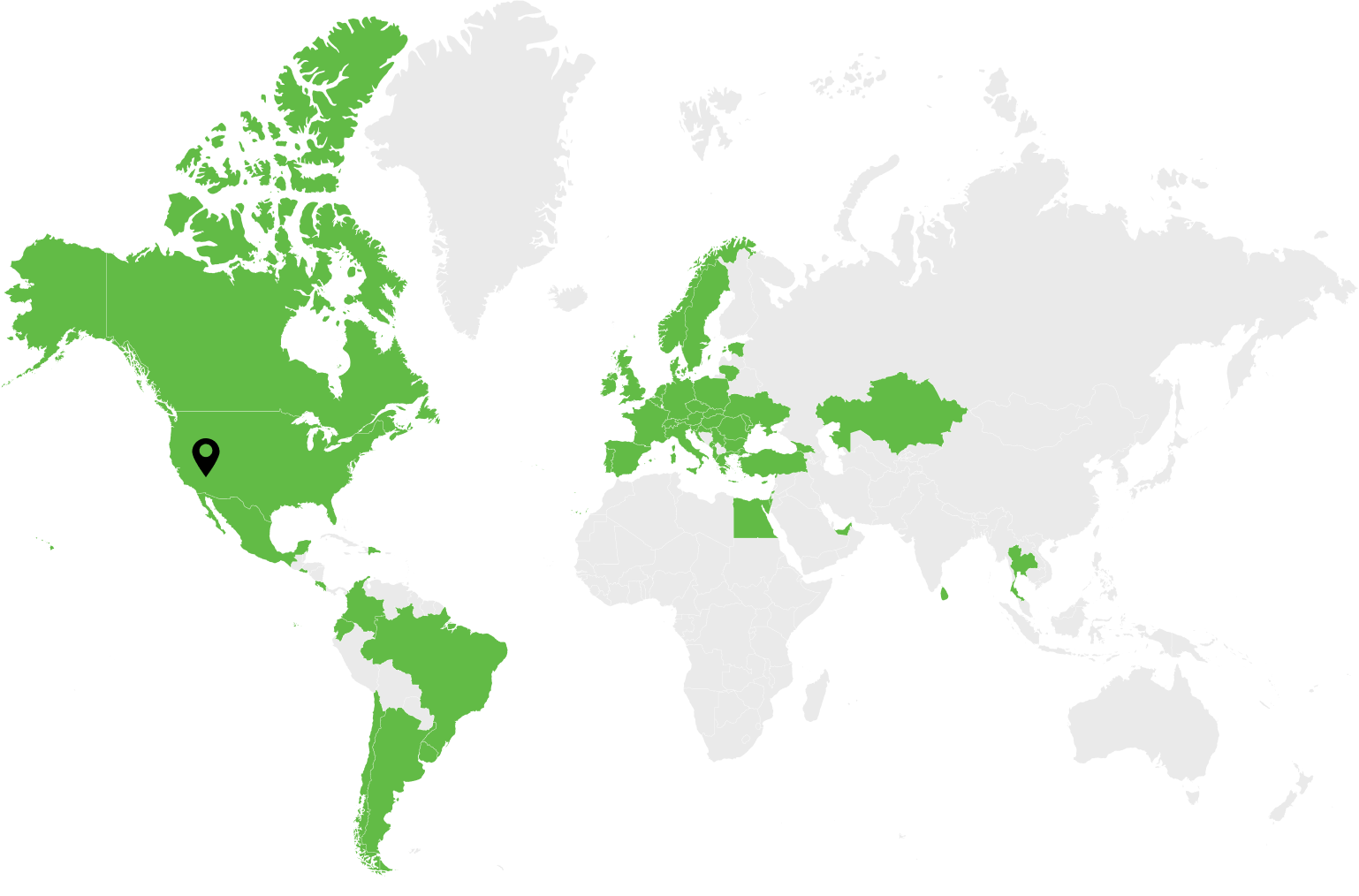

Dev.Pro has been passionate about food tech and restaurant tech since our POS project, like LAVU. Our portfolio in this realm is much wider, though, and our clients include leading restaurant software suppliers. If you need a reliable software development partner to help you develop a restaurant technology platform, speak to our sales department for more information about our hands-on experience in this realm.

Interested in all things F&B? Check out our recent Restaurant Tech State of Play 2022 white paper for trends and key technologies.